Common PLC Issues (and how they can be avoided)

PLCs have been crucial for the advancement of industrial automation. Their ability to increase functionality at decreased cost makes them widely used across automated systems. Not only do they have the ability. PLCs are able to give both simple and complex instructions to a variety of systems.

Like any other machine, PLCs are also prone to breaking and having their own issues. An entire PLC cabinet full of devices, blinking lights, and wires can seem intimidating. However, sometimes the issue might be one that can be resolved simply and easily. So before you call a technician to come service your system, here are a few simple troubleshooting you can do that could save your company some time (and money).

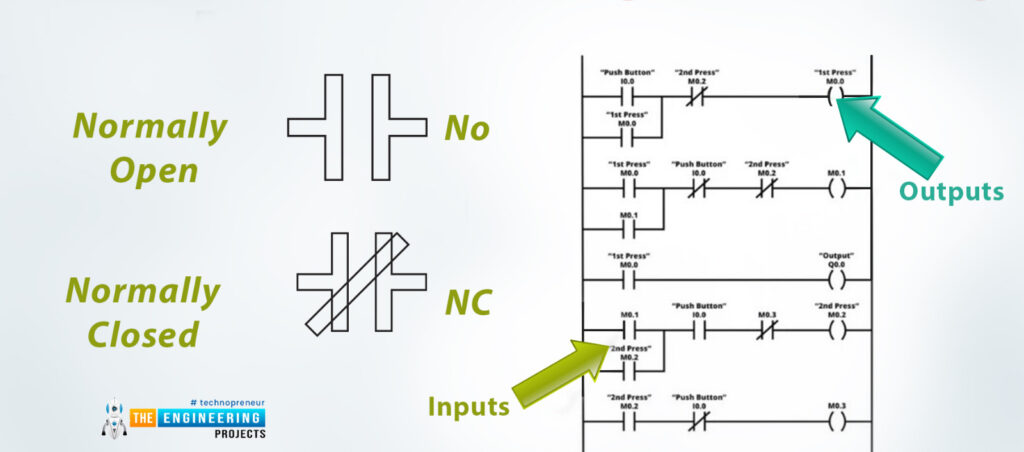

Input/Output(I/O) Failure

This is probably the most common failure that affects PLCs. This is usually due to the relationship between the internal and external situations not establishing a connection. This generally gets fixed by finding out what relationship is not being established and isolating the issue.

Signal Interference

This occurs when there is either electromagnetic interference (EMI) or radio frequency interference (RFI). EMI occurs when a PLC is very close to a large motor or any device that creates an electromagnetic field. Lightning striking a device can also cause an EMI issue. ERFI happens when a PLC is next to a transmitting device for a prolonged period of time. Both of these interference will over time degrade the functionality of a PLC. The best thing to do is to position your PLC somewhere far apart from anywhere that can cause either EMI or RFI. If that is not possible, there are also options for protective housings for your PLC.

Memory Corruption

Corrupt memory issues often occur from interference. They also commonly happen when power to the PLC suddenly gets cut off and not properly rebooted. A popular precautionary measure often taken is simpling backing up data to a storage device. A good preventative measure is to not only keep PLCs away from areas of interference but also places with high temperature and humidity.

Power Loss

In industrial automation, machines rely on consistent power to operate. In the event of a sudden power outage (power grid failure, rolling blackouts, etc) it’s generally a good idea to have an alternate or backup power source to rectify the situation should power failure occur.

Communication

A paramount function for PLCs is their ability to communicate with not only one another but also with other equipment like HMIs and drives. Usually, these devices all communicate via Ethernet cable because of their speed and reliability. Ensuring that wires rest properly connected and away from any obstruction or positioned anywhere that might cause them to crimp or get cut, can help prevent a communication error.

Conclusion

In a perfect world, machines run flawlessly 24/7 with no maintenance required. However, in reality, the inevitability of even the most well-kept facility system failing at some point is unavoidable. That being said, following the steps above can help mitigate the wear and tear of your PLC system and get the most life out of them.