In industrial automation, servo amplifiers play a crucial role in motion control systems. They ensure precise motor operation by controlling voltage and current. One of the key distinctions in servo amplifier operation is whether they use open-loop or closed-loop control. These two control strategies significantly impact system performance, accuracy, and efficiency. Understanding their differences is essential for selecting the right control method for specific applications.

Read more: Closed-Loops vs Open-Loop Control SystemLoop Control System

Before getting into the nitty gritty of knowing the differences between open and closed-loop systems, it’s probably important to establish what a loop control system is in regards to servo amplifiers. A loop control system for a servo amplifier regulates the operation of a motor by adjusting voltage and current based on a control algorithm. This system ensures the motor performs as intended by operating in either an open-loop or closed-loop configuration.

Open-Loop Control System

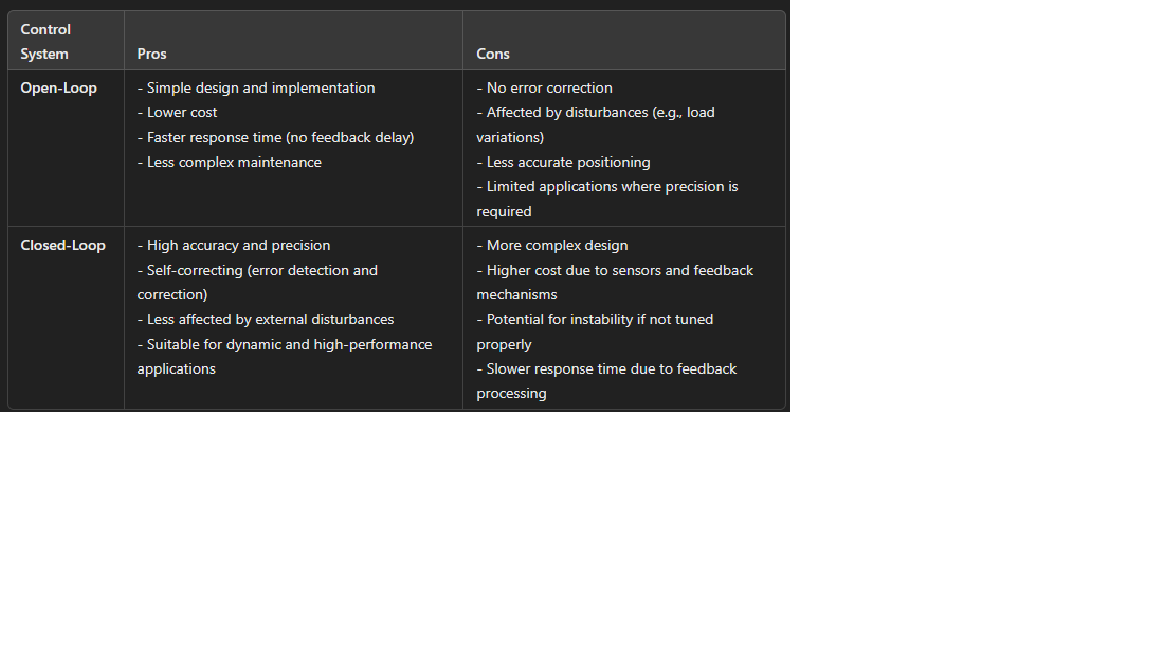

An open-loop control system operates without feedback, meaning the servo amplifier sends commands to the motor without verifying whether the desired motion has been achieved. This approach is simpler and cost-effective, often used in applications where high precision is not a priority. Open-loop systems are commonly found in stepper motor applications, where a predefined sequence of electrical pulses determines movement. However, these systems are susceptible to inaccuracies due to external disturbances, such as load variations or mechanical wear, since they lack a mechanism to correct errors.

Closed-Loop Control System

A closed-loop control system continuously monitors and adjusts motor performance. They perform this using real-time feedback from sensors like encoders or resolvers. Unlike open-loop systems, closed-loop control measures actual motor position, speed, or torque and compares it to the desired set-point. This allows the servo amplifier to make instant corrections if deviations occur. The results are higher accuracy, improved stability, and better responsiveness. This makes closed-loop systems ideal for precision applications such as robotics, CNC machines, and industrial automation. By compensating for disturbances, mechanical variations, and load changes, closed-loop servo amplifiers enhance reliability and efficiency, though they require more complex hardware and tuning compared to open-loop systems.

Conclusion

The choice between open-loop and closed-loop control ultimately depends on the application’s requirements. Open-loop systems are suitable for cost-sensitive applications where precision is not critical. In contrast, closed-loop systems excel in environments demanding accuracy, adaptability, and reliability. As automation technology advances, closed-loop control is becoming increasingly prevalent, offering enhanced efficiency and performance across various industries.

Having Issues With Your Servo Amplifier?

Do you have a servo amplifier not breaking down or not working? Let our team of experts help you get back up and running as soon as possible.

Updated on July 31, 2025 by Ken Cheng