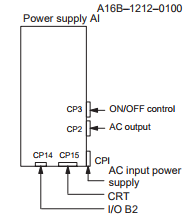

Recently we had a customer who was working on troubleshooting a FANUC CNC Power Supply alarm that he had on a machine. He was wondering what the different codes stood for, so we wanted to go ahead and list the different alarm codes for this series. These codes apply to power supplies that start with the following prefixes. The “X”s after the H will be numbered, so an example part number is A06B-6087-H130.

A06B-6081-HXXX

A06B-6083-HXXX

A06B-6077-HXXX

A06B-6091-HXXX

A06B-6120-HXXX

A06B-6140-HXXX

A06B-6110-HXXX

Here is a list of the alarm codes for these series of Power Supply Modules.

AL01: The main circuit power module (IPM) has detected am Error (PSM-5.5,-11)

Overcurrent flows into the input of the main circuit (PSM-15 to –30).

AL02: A cooling fan for the control circuit has stopped.

AL03: The Temperature of the main circuit heat sink has risen abnormally.

AL04: In the main circuit the DC voltage (DC Link) has dropped.

AL05: The main circuit capacitor was not recharged within the specified time.

AL06: The Input Power Supply is abnormal (open phase).

AL07: In the main circuit the DC Voltage at the DC link is abnormally high.

Be sure to check out our article covering FANUC CNC Troubleshooting Frequently Asked Questions here.

A06B-6087-H130 alarm codes

For more information or to get a quote on a FANUC power supply, please call 800-691-8511 or email sales@mroelectric.com.

We also provide repair services for FANUC Power Supplies.