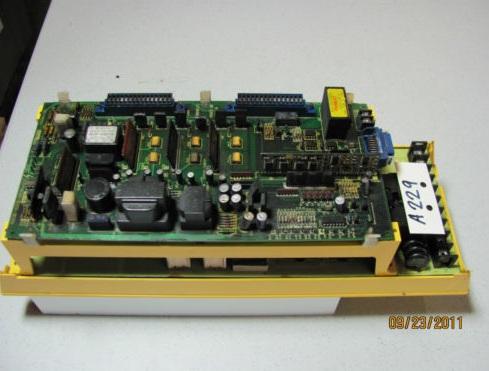

A06B-6058-H005: Beyond the User Manual

Generally, Fanuc AC servo motors, like the A06B-6058-H005, have no parts that wear off or that must be replaced periodically, unlike DC servo motors, which have brushes that must be replaced. However, you should perform period maintenance for servo motors so as to keep their initial performance as long as possible and to prevent breakdowns. AC servo motors have precision sensors — their incorrect use or damage caused during transportation or assembling can result in breakdowns or accidents.

It is recommended that you inspect servo motors periodically, and of course we offer a 12 month warranty on all Fanuc products purchased from MRO Electric.

Receiving and Keeping the A06B-6058-H005

When you receive a A06B-6058-H005 module from MRO Electric, make sure that the motor is exactly the one you ordered, in terms of model, shaft, and sensor specifications, and make sure that no damage has been caused on the motor. Servo motors should be kept indoors as a rule. The storage temperature range is -20 to +60 Celsius. Do not place or install AC servo motors in a place where it is extremely humid and dew is prone to form, where there are steep changes in temperature, where there is constant vibration, or there is lots of dust and trash. Constant vibration may cause damage to the shaft bearings.

Daily Inspection Procedures

Before starting operation, or periodically (once a week or month), you should inspect the AC servo motors for vibration and noise, outside damage, stains and smudges, overheating.

Check the motor for abnormal vibration by hand, and noise by ear when the motor is not rotating, rotating at low speed, and accelerating and decelerating.

Check the Pulsecoding cover (read plastic) for crevices and the motor surface (black coating) for scratches and cracks. If you find a crevice on the Pulsecoder cover, you should replace it. If there is a scratch or a crack on the motor surface, the user should repair it by himself as required. If coating has come off, dry the portion of interest or the entire surface and coat it with paint for machines such as urethane paint.

Check the motor surface and bolt holes for oil or cutting fluid. Wipe off oil and cutting fluid on the surface periodically. Oil or cutting fluid can damage the coating by chemical reaction, possibly leading to failure. Also check how such liquid leaks onto the motor, and repair if needed.

Check to see if the motor is too hot during normal operation. Attach a thermolabel on the motor surface and check it visually to see if the motor becomes too hot during normal operation.

Visit our A06B-6058-H005 product page for more information, or to request a quote email sales@MROElectric.com or call 1-800-691-8511

Updated on March 5, 2020 by Brian Hughes