In today’s highly automated world, machines and industrial processes are controlled by sophisticated electronic devices that ensure efficiency, precision, and safety. One of the key players in this realm is the Programmable Logic Controller (PLC). PLCs are the unsung heroes behind the automation of countless industries, from manufacturing and agriculture to energy production and beyond. In this comprehensive guide, we will delve deep into the world of PLCs to understand how they work, their applications, components, programming, and their significance in modern industrial automation.

Chapter 1: The Basics of PLCs

1.1 What is a PLC?

A Programmable Logic Controller (PLC) is a specialized computer designed to control and automate industrial processes and machinery. Unlike general-purpose computers, PLCs are tailored for reliability, ruggedness, and real-time control. They are commonly used in manufacturing plants, chemical processing, power generation, and various other industries.

1.2 Why Use PLCs?

PLCs offer several advantages over traditional relay-based control systems:

- Flexibility: PLCs are highly adaptable and can be reprogrammed to handle different tasks without the need for hardware changes.

- Reliability: PLCs are known for their robustness, with long lifespans and resistance to environmental factors.

- Real-time Control: They provide precise control over processes with minimal delay.

- Diagnostics: PLCs offer extensive diagnostic capabilities, making troubleshooting and maintenance easier.

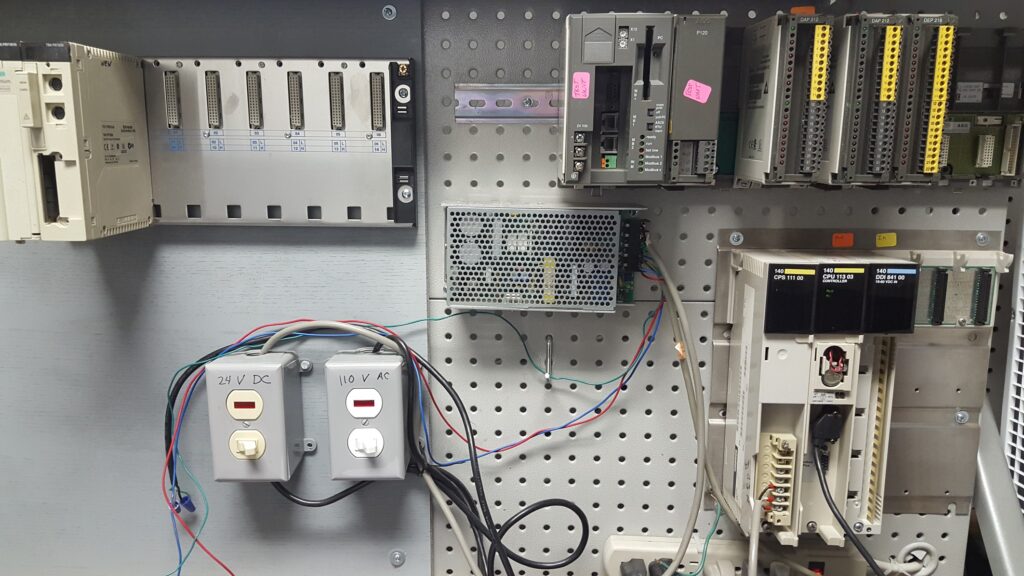

Chapter 2: Components of a PLC

2.1 Central Processing Unit (CPU)

The CPU is the brain of the PLC, responsible for executing control programs. It interprets input data, processes it according to the program, and sends output signals to control devices. The CPU also manages memory, communications, and system functions.

2.2 Input Modules

Input modules are responsible for collecting data from the physical world. These can include digital inputs (for on/off signals) and analog inputs (for continuous data like temperature or pressure).

2.3 Output Modules

Output modules receive signals from the CPU and control physical devices. They can be digital (for activating relays or motors) or analog (for varying voltage or current outputs).

2.4 Memory

PLCs have different types of memory:

- Program memory stores the user-created control program.

- Data memory holds variables and data used in the program.

- Non-volatile memory retains the program and data even when the PLC is powered off.

2.5 Communication Ports

Many modern PLCs include communication ports to interact with other PLCs, HMI (Human-Machine Interface) devices, or supervisory systems.

Chapter 3: Programming PLCs

3.1 Ladder Logic

Ladder Logic is the most common programming language for PLCs. It mimics traditional relay logic diagrams, making it intuitive for control engineers. Ladder Logic consists of rungs, with each rung representing a control function.

3.2 Function Block Diagrams (FBD)

FBD is another graphical programming language used for PLCs. It represents control functions as blocks connected by lines. FBD is particularly useful for complex processes with many interrelated functions.

3.3 Structured Text (ST)

Structured Text is a high-level programming language resembling Pascal or C. It’s suitable for advanced control algorithms and complex calculations. ST is less common in PLC programming but offers greater flexibility.

3.4 Sequential Function Charts (SFC)

SFC is a graphical language used for complex sequencing and state-based control. It’s excellent for modeling processes with multiple stages or modes.

Chapter 4: Input and Output Processing

4.1 Input Processing

When the PLC receives input signals, it scans its input modules to read the current state of each input point. It stores this information in memory for use in the control program.

4.2 Output Processing

After processing the inputs and executing the control program, the PLC updates the output modules. This action can involve turning on or off devices, adjusting analog output values, or performing other control actions.

Chapter 5: PLC Scan Cycle

The PLC operates in a continuous scan cycle, which typically consists of the following steps:

- Input Scan: The PLC reads the state of all input devices.

- Program Execution: The CPU executes the control program based on the input data.

- Output Scan: The PLC updates the output devices based on the program’s logic.

- Housekeeping: The CPU manages system tasks, updates timers and counters, and checks for errors or faults.

- Repeat: The cycle continues indefinitely, typically at a high speed (milliseconds to microseconds).

Chapter 6: PLC Memory and Data Handling

6.1 Data Types

PLCs support various data types, including integers, floating-point numbers, boolean values, and strings. Engineers must use the appropriate data type for each variable to ensure accurate processing.

6.2 Memory Organization

PLC memory is organized into discrete areas for program storage, data storage, and system information. Managing memory effectively is crucial to ensure efficient program execution.

Chapter 7: PLC Networking and Communication

7.1 Industrial Networks

PLCs often communicate with other devices and systems through industrial networks like Ethernet/IP, Modbus, Profibus, and DeviceNet. These networks allow data exchange between PLCs, HMIs, and other controllers.

7.2 Human-Machine Interface (HMI)

HMIs provide operators with a visual interface to monitor and control processes. PLCs can communicate with HMIs to display real-time data, alarms, and control options.

Chapter 8: PLC Safety and Redundancy

8.1 Safety Features

PLCs are equipped with safety features such as watchdog timers and error handling to ensure reliable operation. Redundancy in critical systems further enhances reliability by providing backup PLCs in case of a failure.

8.2 Fault Tolerance

In applications where downtime is critical, fault-tolerant PLC systems are used. These systems include redundant CPUs and I/O modules to ensure continuous operation even in the event of component failure.

Chapter 9: PLC Applications

9.1 Manufacturing

PLCs are extensively used in manufacturing for tasks like assembly line control, quality control, and inventory management.

9.2 Energy and Utilities

In power plants and utility systems, PLCs control processes such as energy generation, distribution, and monitoring.

9.3 Agriculture

PLCs help automate various agricultural processes, including irrigation, livestock feeding, and greenhouse control.

9.4 Automotive Industry

PLCs are integral to automotive manufacturing, controlling robotic assembly lines and quality control processes.

9.5 Building Automation

PLCs are used for building automation, managing HVAC systems, lighting, security, and access control.

Chapter 10: Troubleshooting and Maintenance

10.1 Diagnostic Tools

PLCs offer diagnostic tools to help identify faults and errors in the system, making troubleshooting more efficient.

10.2 Preventive Maintenance

Regular maintenance is essential to ensure the long-term reliability of PLC systems. This includes checking for loose connections, cleaning components, and updating firmware.

Chapter 11: Future Trends in PLC Technology

11.1 Industry 4.0 and IIoT

PLCs are evolving to be a crucial part of Industry 4.0, with a focus on connectivity, data analytics, and cloud integration.

11.2 Machine Learning and AI

PLCs are incorporating machine learning and AI algorithms for predictive maintenance and process optimization.

11.3 Edge Computing

Edge computing is becoming increasingly important in PLCs, enabling real-time decision-making at the machine level.

Conclusion

Programmable Logic Controllers play an indispensable role in modern industrial automation. They have revolutionized the way industries operate by providing reliable, real-time control over processes. Understanding the components, programming languages, and applications of PLCs is essential for engineers and technicians working in automation. As technology continues to advance, PLCs will remain at the forefront of innovation, driving greater efficiency and precision in industrial processes.