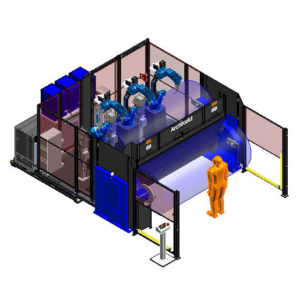

Yaskawa’s ArcWorld 6000 line of robotic welding systems offer the most cost efficient and powerful solution to your welding needs. ArcWorlds are pre-built, easy to install, and ready to run immediately after installation. The units can configured with multiple robots, a heavy duty positioner or servo controlled external axes. The 6000 line can handle payloads from 755 kg to 1255 kg over a 2 or 3 meter span. There are many other cool benefits to running the ArcWorld over a traditional welding system:

- All controllers and power sources are installed and shipped on the frame for minimal setup

- The world class MA1440 arc used for welding can be combined with multiple robots to cut cycle time by 15%

- Twist locking connectors for all cabling

- Fully compliant with most recent robot safety standards (ANSI/RIA R15.06-2012)

- A standard workcell is only documented and supported by Yaskawa Motoman

The RM2-Series Positioners are are powered with three AC servo motor drives and have a payload capacity of 1555 on each side. With a 6.5 second rapid indexing time, the positioners have a part length between 3000mm and 3500mm. Convenient slip ring built for the fixture of utilites such as Ethernet and DeviceNet. The positioner uses MotoMount mounting technology inside of the Yaskawa ArcWorld Unit.

Typically used inside of the ArcWorld 6000 line is the DX200 controller. These controllers can coordinate motion between 8 robots with up to 72 axes. Its Advanced Robot Motion control gives the ArcWorld unit the ability to use the arc’s at their peak performance with pinpoint precision. DX200 controllers are available with Cat 3 Functional Safety Unit. Maintenance is hardly necessary as these controllers efficiently use energy and use top of the line prevention methods for most types of failures. Contact Yaskawa Motoman right now to inquiry on price options for different ArcWorld models and make your automation system perform at its best.

Updated on May 15, 2020 by David Link