It is important to understand the differences between faults and alarms on Sinamics S120 Drives by Siemens. We have included a list of common faults and alarm codes for S120 drives, what they mean, likely causes and how to fix the fault or alarm. For more Sinamics S120 faults and alarms, check out Part II and Part III of the series that we will be posting shortly. Be sure to check out our website to browse all of our Siemens products.

Understanding Faults

Sinamics S120 Fault Codes Numerical Ranges

When operating Sinamics S120, various errors can arise that may impact the machine’s performance. These faults are typically accompanied by error messages. The fault codes for Sinamics S120 are organized into numerical ranges, each corresponding to a specific type of issue:

- F0001 – F0099: Control unit

- F0100 – F0199: Reserved

- F0200 – F0299: Power supply

- F0300 – F0399: Feed unit

- F0400 – F0499: Drive

- F0500 – F0599: Option board

- F0600 – F2999: Reserved

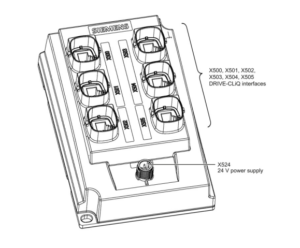

- F3000 – F3099: DRIVE-CLiQ component power section

- F3100 – F3199: DRIVE-CLiQ component encoder 1

- F3200 – F3299: DRIVE-CLiQ component encoder 2

- F3300 – F3399: DRIVE-CLiQ component encoder 3

- F3400 – F3499: Reserved

- F3500 – F3599: Terminal Module 31

- F3600 – F4999: Reserved

- F5000 – F5039: Communication Board (COMM BOARD)

- F5040 – F65535: Reserved

This classification aids in swiftly identifying the type of problem based on the fault code range, making troubleshooting more efficient.

What happens when a fault occurs?

- The appropriate fault reaction is initiated

- Status signal ZSW1.3 is set.

- The fault is entered in the fault buffer.

How are faults eliminated?

- Remove the original cause of the fault

- Acknowledge the fault

Understanding Alarms

What happens when an alarm occurs?

- Status signal ZSW1.7 is set.

- Alarms are “Self Acknowledging” meaning they are reset when the cause of the alarm has been eliminated.

List of Sinamics S120 Faults and Alarms

F01000: Internal software error

Message Value: Module: %1, Line: %2

Drive Object: All Objects

Reaction: OFF2

Acknowledge: POWER ON

Cause: An internal software error has occurred. Fault value (r0949, interpret hexadecimal)

Remedy:

- Evaluate fault buffer

- Carry out a POWER ON (power on/off) for all components.

- If required, check the data on the non-volatile memory (memory card).

- Upgrade firmware to a later version.

- Replace the control unit or contact MRO Electric.

F01001: Floating Point Exception

Message Value: %1

Drive Object: All objects

Reaction: OFF2

Acknowledge: POWER ON

Cause: An exception occurred during an operation with the FloatingPoint data type. The error may be caused by the basic system or the OA application (e.g. FBLOCKS, DCC).

Remedy:

- Carry out a POWER ON (power on/off) for all components.

- Check configuration and signals of the blocks in FBLOCKS.

- Check configuration and signals of DCC charts.

- Upgrade firmware to a later version.

- Contact Service Hotline.

F01002: Internal software error

Message Value: %1

Drive Object: All objects

Reaction: OFF2

Acknowledge: IMMEDIATELY

Cause: An internal software error has occurred.

Remedy:

- Carry out a POWER ON (power on/off) for all components.

- Upgrade firmware to a later version.

- Contact Service Hotline.

F01003: Acknowledgement delay when accessing the memory

Message Value: %1

Drive Object: All objects

Reaction: OFF2

Acknowledge: IMMEDIATELY

Cause: A memory area was accessed that does not return a “READY”.

Remedy:

- Carry out a POWER ON (power on/off) for all components.

- Contact Service Hotline

N01004 (F, A): Internal software error

Message Value: %1

Drive Object: All objects

Reaction: NONE

Acknowledge: NONE

Cause: An internal software error has occurred.

Remedy: Read out diagnostics parameter (r9999).

Reaction upon F: OFF2

Acknowl. upon F: POWER ON

Reaction upon A: NONE

Acknowl. upon A: NONE

F01005: Firmware download for DRIVE-CLiQ component unsuccessful

Message Value: Component number: %1, fault cause: %2

Drive Object: All objects

Reaction: NONE

Acknowledge: IMMEDIATELY

Cause: It was not possible to download the firmware to a DRIVE-CLiQ component

Remedy:

- Check the selected component number

- Check the DRIVE-CLiQ connection

- Save suitable firmware file for download in “/siemens/sinamics/code/sac/”

- Use a component with a suitable hardware version

- After POWER ON has been carried out again for the DRIVE-CLiQ component, download the firmware again. Depending on p7826, the firmware will be automatically downloaded.

A01006: Firmware update for DRIVE-CLiQ component required

Message Value: Component number: %1

Drive Object: All objects

Reaction: NONE

Acknowledge: NONE

Cause: The firmware of a DRIVE-CLiQ component must be updated as there is no suitable firmware or firmware version in the component for operation with the Control Unit.

Alarm value (r2124, interpret decimal): Component number of the DRIVE-CLiQ component

Remedy:

- Firmware update using the commissioning software:

- The firmware version of all of the components on the “Version overview” page can be read in the Project Navigator

under “Configuration” of the associated drive unit and an appropriate firmware update can be carried out.

- Firmware update via parameter:

- Take the component number from the alarm value and enter into p7828.

- Start the firmware download with p7829 = 1.

A01007: POWER ON for DRIVE-CLiQ component required

Message Value: Component number: %1

Drive Object: All objects

Reaction: NONE

Acknowledge: NONE

Cause: A DRIVE-CLiQ component must be powered up again (POWER ON) (e.g. due to a firmware update).

Alarm value (r2124, interpret decimal): Component number of the DRIVE-CLiQ component. If the component number is 1, a POWER ON of the Control Unit is required.

Remedy:

- Switch off the power supply of the specified DRIVE-CLiQ component and switch it on again.

- For SINUMERIK, auto commissioning is prevented. In this case, a POWER ON is required for all components and the auto commissioning must be restarted.

A01009 (N): CU: Control module overtemperature

Message Value: –

Drive Object: All objects

Reaction: NONE

Acknowledge: NONE

Cause: The temperature (r0037[0]) of the control module (Control Unit) has exceeded the specified limit value.

Remedy:

- Check the air intake for the Control Unit.

- Check the Control Unit fan.

MRO Electric and Supply carries new and used Sinamics modules. For more information or to request a quote, call 800-691-8511 or email sales@mroelectric.com.

Dealing with Sinamics S120 Fault Codes?

Fault codes on your Sinamics S120 can be a major setback. MRO Electric provides the expertise and parts you need to diagnose and resolve issues swiftly, ensuring your drive system runs smoothly without extended downtime.